The exhaust air in process ventilation often has characteristics like; high temperatures, high air flows and many operating hours per day. The pollutants and particles in the exhaust has – until now – made it troublesome to recover the inherent energy in these air flows. The available heat exchanger technologies have been prone to clogging, which in turn has forced most industrial producers to accept that the exhaust is released into the ambient air, without any energy recovery.

The result is that copious amounts of energy is released as waste heat from process ventilation, as it has been considered impossible or too costly to recover this energy. Our technology pushes the boundaries between what should be considered waste heat and what should be considered available energy.

Enjay have developed an industrial heat exchanger specifically designed to operate in polluted air streams, which enables us to transform waste heat into available energy, without jeopardizing the production output.

A lot of the energy that up until now has been considered waste heat, really should be re-classified and via energy recovery be reintroduced into either the production process or other adjacent energy systems.

How to identify new sources of energy?

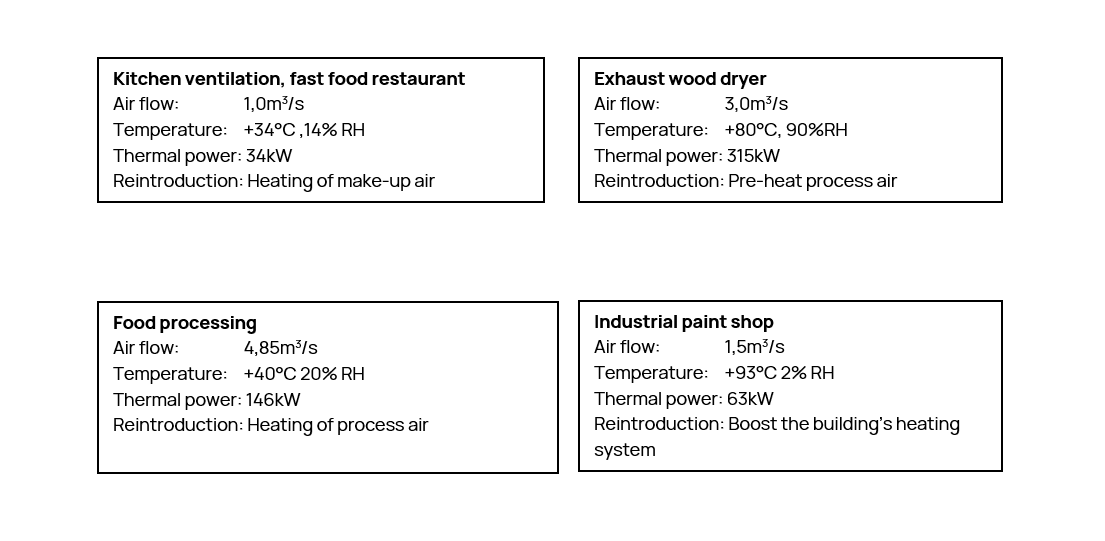

The following are some examples, where the inherent energy in the process air used to be classified as waste heat, but from now on should be considered viable sources of energy:

- Ovens – examples include bakeries, foundries, and other food processing.

- Drying processes – examples include wood dryers and industrial paint shops

- Food processing – examples include deep frying, frying and boiling

- Compressor rooms

- Welding and soldering halls

- Plastic and rubber production

How can the energy recovered from waste heat be reintroduced?

To make a dent in the energy consumption for the site, the recovered energy needs to find a system where it can be reintroduced profitably. With the energy costs soaring also for industrial customers, they have had to start questioning some old truths, accepting that the new cost level enables large savings within areas where energy recovery used to be labeled unprofitable.

Some examples:

- Make-up air to premises, warehouses, and adjacent buildings

- Circulation air heaters in premises, warehouses, and adjacent buildings

- Pre-heat of process air, for example in dryers or paint boxes

- Warming of process fluids, for example in laundries and cookeries

- Pre-heat of hot water and/or boosting the building’s heating system

Benefiting from the fact that process ventilation offer both high temperatures and high air flows, the recovered energy can often replace a large share of the required thermal power and simultaneously contribute to a more circular energy system for the building, or potentially for the whole site.

Examples:

The thermal power varies based on air flows, temperatures, and prerequisites in the system where the energy is reintroduced. Summarizing a large number of projects, we can identify a couple of generic examples.